Quartz

QUARTZ :

The quartz are used in a wide range of applications from jewellery making, industrial applications and many electronic appliances. Each crystal has a unique property and is extracted through unique methods. However the common method to extract the ore is open pit mining. As the demand of the quartz increased, modern technologies were involved to produce the quartz.The quartz with specialized property allows it to grow in laboratory conditions called cultured quartz.

Main sources of Quartz

Quartz is a crystalline of silica that is found on the average amount of 58% to 63% on the earth surface and occurs in all types of rocks including igneous, metamorphic and sedimentary rocks. They are widely distributed in the following countries: Brazil, USA, Canada, Norway, Russia, India, China and Australia which produce high purity quartz.

Largest producer of quartz:

The largest producer of natural quartz in Brazil.The Telequartz Group of Mining Companies in Brazil is the largest and well established exporter of Quartz in the world. The natural crystals that are generally available contain high physical and chemical impurities. So high physical and chemical treatments are required to remove the impurities. Another largest producer of Quartz is the United States of America. The most purest quartz deposit is found in the Spruce pine, North Caroline, USA. It is present 780m above the sea level, where geology offers the highest purity quartz deposits.

These are some of the mines to produce the purest form of the quartz crystal.

Quartz is generally extracted from the open pit mines. There are different types of crystal in this family, but almost all the crystals are extracted from this method. In this method, the top soil or overburden material covering the crystal is removed and kept for refill purposes. This method is followed when the mineral deposits are present in the lower depths. The crystals are extracted by hand tools or with the help of the heavy load machineries like bulldozers and backhoes. In case if the overburden is hard and cannot be removed manually, the explosives are employed. The blast method is only used to remove the overlying material. In case of the extraction of the quartz, the explosives are not employed as it may cause damage in the crystal due to change in temperature. Even though it is recognised for its hardness, the brittle structure of the quartz gets damaged easily when it is prone to high pressure and temperature.The open pit mine is dug until the quartz crystals in the veins of the rock are exposed. The quartz crystal is then removed manually with hand tools.

Cultured quartz

For the rising industrial needs of the quartz, they are grown carefully in highly controlled and specialised laboratory conditions. The seed crystal is the small piece of the non electronic grade quartz that has been carefully selected for the growth of the cultured quartz.It produces about 200 metric tons of quartz each year for industrial purposes. This quartz is used in electrical and electronic appliances such as computers, cellphones, television, radios and electronic games.

Underground mining

In underground mining,the quartz crystals are identified by the different mining methods like shaft and tunnel mining, roof and pillar mining and through the slope mining. For the extraction of the crystal, the rock which comprises the quartz crystal is allowed to decompose in the process of weathering. As quartz is the most resistant component, the other least resistant component tends to dissolve first and destabilizes the entire structure.Therefore the brittle components which go through chemical weathering shatter it until it is sand and it forms the hard rock. To dissolve the quartz component separately the thermal groundwater with certain ph value water is allowed to pass over it. Then the quartz will deposit on the subterranean space, which are then collected and sent for further processing.

The top 10 Quartz exporting countries in 2017

Processing of Quartz crystal

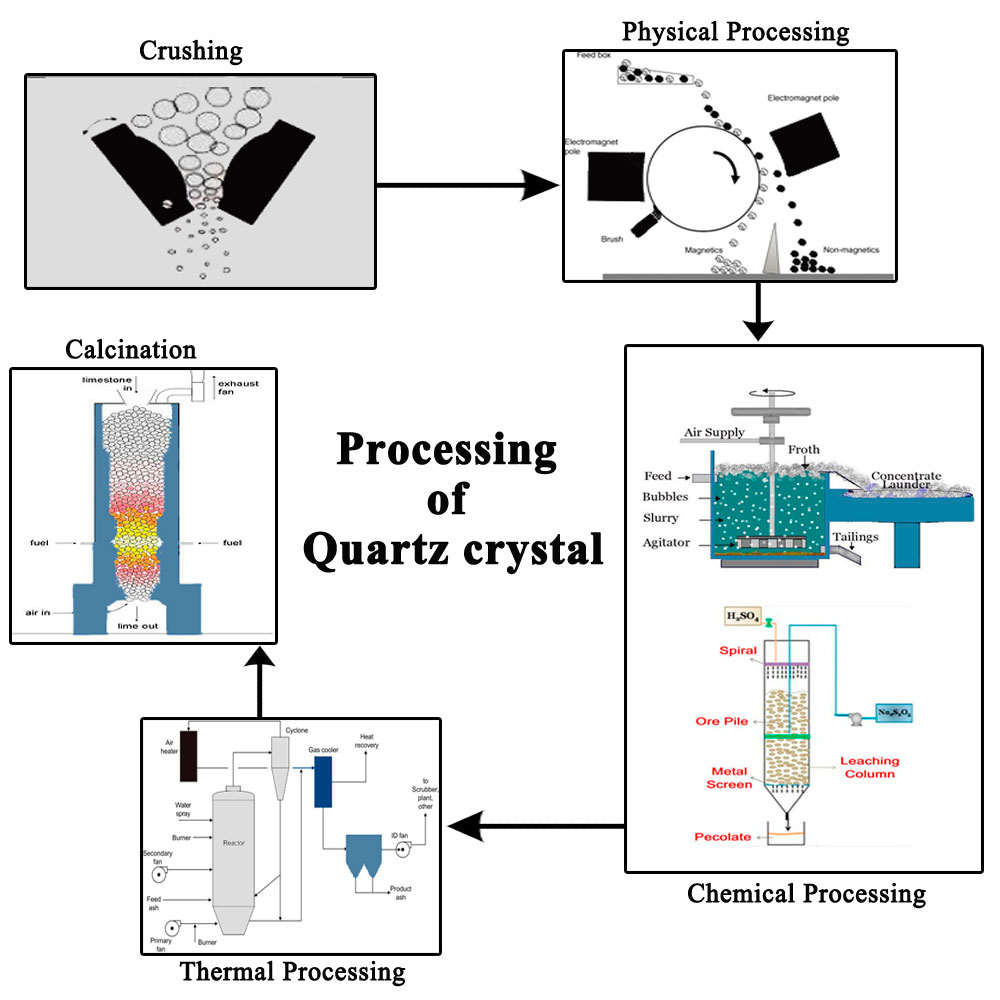

The processing of the quartz crystal depends on the amount, origin and the type of impurities present in the ore. After the quartz is successfully mined, it must go through a series of steps to remove its flaws.The process includes crushing, screening, floating and other chemical techniques.

They can be classified into four to six stages:

Crushing: this is the first stage after mining, in which the quartz chunks are sent to the jaw crusher for breaking up the large lumps. It is also done by forklift or manpower. These crushed pieces are then washed and scrubbed.

Physical processing: the physical process involves cleaning the surface of the quartz. In magnetic separation and high tension separation the minerals and quartz are separated depending on the surface charge.

Chemical processing: floatation and acid leaching are the two primary processes in which the trace minerals from the quartz are removed. Acid leaching helps to decrease the impurities. The combination of chemical substances like HF, HCL, HNO3 to improve the results.

Thermal processing

In thermal or hot chlorination processes, the quartz is heated upto temperature of 1200 degree celcius in a chlorine or hydrogen gas atmosphere. This method is essential to remove the alkali, alkali earth and transition metals.

Calcination:

It improves the melting properties of the high purity quartz and reduces the fluid inclusions.