Tin Mining

TIN :

Tin, a rare element found in the Earth's crust at approximately 2 ppm, contrasts with iron, which has 50,000 ppm. It's a silvery-white metal prized for its corrosion resistance and ability to impart a polished appearance when used as a coating on other metals. While there are nine tin-bearing ores in the Earth's crust, only cassiterite is actively mined.

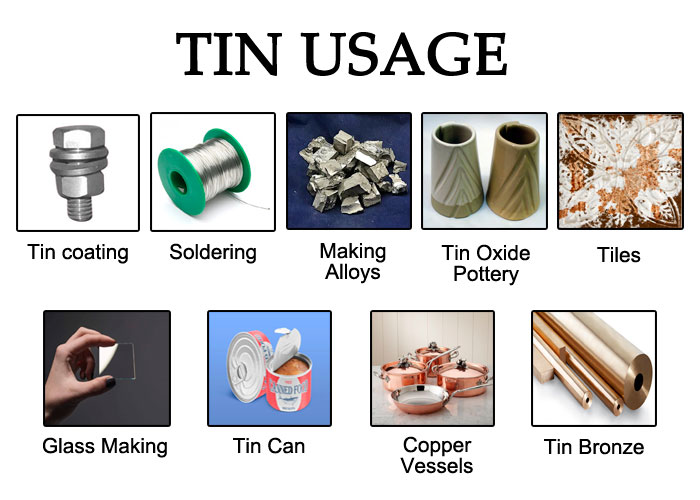

USAGE:

It is ideal for coating, soldering, and making alloys. Tin oxide is used in pottery, tiles, and glassmaking to provide the white glaze. It is mainly used in canned foods for packaging containers. Copper vessels are often coated with tin to keep them looking bright. Tin is also used to make bronze when mixed with copper.

RESOURCES:

Most of the world's tin is mined and produced in China, Malaysia, Bolivia, Indonesia, Thailand, Australia, Nigeria, and England. Countries such as Canada, Spain, and Japan also produce a small amount of tin. About 80 percent of the tin is deposited in alluvial soil or found along the seabed.

https://www.internationaltin.org/wp-content/uploads/2020/02/Global-Resources-Reserves-2020-Update.pdf

TIN MINING AND PROCESSING:

The tin on land is recovered either by open-pit mining or underground mining. When it is present on the seabed, it is mined by dredging the seabed.

Underground mining:

Tin ore is typically found in veins, such as those within granites, and is extracted using underground mining techniques, a common practice in countries like Bolivia and the United Kingdom. In hard rock mining, various methods are employed based on the characteristics of the tin ore deposits. After extraction, the ore is fragmented into smaller pieces to facilitate transportation.

Surface mining:

The shallow deposits of fine-grained minerals, often found on riverbeds or in valleys, constitute the more productive alluvial fields. The ore in these areas is typically recovered through open-pit mining. Gravel pumping, one of several surface mining techniques, is commonly used to extract a significant portion of the tin ore. The initial step involves removing the barren overburden using draglines or shovels. High-pressure water is then used to dislodge the hard tin-bearing sand, creating a slurry. This slurry of mud and water is suctioned up by submerged gravel pumps and passed through a series of sluice boxes or palongs to separate the elements. Cassiterite, the heaviest mineral, settles to the bottom, while lighter waste is carried away to tailing dumps.

dredging:

In cases where the ores are deposited in areas submerged underwater or at the water level, alluvial deposits are flooded by diverting a river. Alternatively, they are brought up using a floating dredge and stored in an artificial pond for tin recovery. A mining dredge equipped with an endless bucket is floated to dig and lift the tin-bearing ore, which is then sent to the primary processing plant for further treatment.

The concentrated ores are recovered using gravity separation methods such as jigs and shaking tables, while the waste material is discharged over the stern. Countries like Bolivia have impure ore, whereas the alluvial mining areas of Southeast Asia are either free of impurities or contain trace amounts of minerals like wolframite, scheelite, and columbite. These regions can produce up to 75 percent pure tin from these ores.

Extraction and refining:

To remove the sulfur from the complex ore, the ores are first roasted in a reverberatory hearth furnace at temperatures between 550 and 650 degrees Celsius. After roasting, the process involves leaching with water or acid to remove the waste materials. Oxidation, reduction, and chlorination reactions take place depending on the type and quantity of impurities in the ore.

The principle of producing tin involves heating tin oxide with carbon to produce the metal tin and carbon dioxide. Other materials like limestone, silica, and salt are often used in the tin processing and refining process.

Refining tin is done through two processes based on usage. Fire refining is commonly used to produce 99.85 percent pure tin, typically for commercial purposes. Electrolytic refining is employed for treating complex ores, resulting in a higher grade of tin (99.999 percent pure).

Secondary tin, derived from tin-containing scraps, is used to directly produce alloys. Bearings, solder alloys, and bronze are important sources of tin scraps. Electrolytic refining is commonly employed for the production of secondary tin.

MINES AND RESERVES:

China:

China boasts some of the world's largest tin reserves, with approximately 4.5 million tonnes of resources, including 1.2 million tonnes of reserves. With 293 active mining sites, key production areas include Dachang, Shanhu, and Shuiyanba in Guangxi Province, as well as Xianghualing and Dongchuan in Yunnan Province, and Hongqiling and Yejiwei in Hunan Province. China's tin output surpasses that of all other countries by 30%.

Indonesia:

As the second-largest tin producer globally, Indonesia boasts an estimated production of 77.5 kilo tonnes. PT Timah, a state-run company, controls 96% of the country's local tin resources.

Bolivia:

Bolivia's primary tin ore is cassiterite, and one of its notable mines is the Huanuni tin mine, discovered accidentally in 1940. Among the world's largest underground mines, Huanuni faces challenges in processing complex sulphide ore to yield clean tin concentrate, achieving only 50 to 60 percent concentration. Despite its leading position in tin production, Bolivia has encountered economic difficulties, attributed partly to the high-altitude and deep ore deposits, which escalate production costs, causing it to drop from the second to the fifth position among tin producers.

England:

Dartmoor, England's tin mining industry operates within granite country rock, employing various methods from stream extraction and open-pit mining to underground mining to extract cassiterite and produce tin.

Peru:

Minsur's San Rafael Mine, operational since 1975, has been a dominant force in Peru's tin mining industry, producing 550 kilo tonnes of tin over the past decade. Additionally, the Ayawilca project in the Pasco department, primarily focused on zinc production, has also recovered over 90 kilo tonnes of tin.

TOP TIN PRODUCING COUNTRIES :

The top tin producing countries in the world are:

1.China: China leads global tin production, with an estimated output of 130,000 metric tonnes in 2019, primarily from the Yunnan province.

2.Indonesia:Indonesia ranks as the second-largest tin producer worldwide, with an estimated production of 85,000 metric tonnes in 2019. It is also the largest exporter, with exports exceeding 79,000 metric tonnes in the same year.

3.Peru: Peru stands as the third-largest tin producer globally, with an estimated output of 51,000 metric tonnes in 2019. It is also the second-largest exporter, with exports surpassing 38,000 metric tonnes in the same year.

4.Bolivia: Bolivia holds the position of the fourth-largest tin producer globally, with an estimated production of 32,000 metric tonnes in 2019. It is also the third-largest exporter, with exports totaling more than 28,000 metric tonnes in 2019.

5. Brazil: Brazil ranks as the fifth-largest tin producer globally, with an estimated output of 19,000 metric tonnes in 2019. Additionally, it is the fourth-largest exporter, with exports reaching more than 15,000 metric tonnes in the same year.

ANNUAL TIN USAGE :

Tin, a malleable and ductile metal, finds extensive applications across various industries. It serves as a primary constituent in solder, facilitating the joining of electrical components and metal surfaces. Additionally, tin is integral in manufacturing cans and containers for food and beverages, pipes, automotive alloys, coins, and jewelry. Moreover, it is utilized in paints, building materials, batteries, and electrical components. Its versatility extends to aerospace, where it is utilized in alloy production.

TIN PRODUCTION IN THE WORLD :

The global tin production industry is dominated by a few major players, with China, Indonesia, Peru, Bolivia, and Myanmar leading the pack. China holds the title of the world's largest producer, contributing an estimated 31% of global production in 2020. Indonesia follows closely as the second-largest producer, accounting for approximately 11% of global production. Peru and Bolivia rank third and fourth, respectively, each contributing around 8% and 7% of global production. Myanmar rounds out the top five producers with an estimated 4% of global production.

The production of tin is primarily concentrated in Asia, particularly in China, Indonesia, and Myanmar, which collectively account for the majority of global production. However, other regions also play a role in tin production, including Latin America (Peru and Bolivia), Africa (Nigeria and Congo), and Europe (Portugal). Tin finds its primary use in the production of tin alloys like solder, pewter, and bronze. Additionally, it is employed in various tin-based chemicals such as tin oxide and pigments, as well as in the manufacturing of tin containers like cans and aerosols. Moreover, tin serves critical roles in the electronics industry, jewelry making, and coin minting.