Titanium Mining

TITANIUM:

Titanium is one of the Earth's most abundant elements, which is practically present in every rock, soil, plant, animal, and deep ocean. Even though it is widely distributed in the Earth's crust and lithosphere, it is extracted from ores such as rutile and ilmenite, which contribute about 10% and 90% respectively to global titanium extraction. As an abundant element, it is extracted almost everywhere in the world; among the major countries involved are China, South Africa, Canada, Mozambique, India, Ukraine, Norway, Senegal, Madagascar, the United States, Vietnam, Kenya, Brazil, Australia, Malaysia, and Sierra Leone.

ORES:

Ilmenite is the dominating ore mined for the production of titanium, comprising iron and titanium in the composition of FeTiO3. It is found in common rock sediments around the world and even on the moon's lunar surface. The slow cooling and magmatic segregation of magma chambers result in the formation of ilmenite in the Earth's crust. Larger deposits of titanium-bearing ilmenites are found in Western Australia, China, India, South Africa, Mozambique, and Canada.

Rutile is another ore of titanium which naturally contains an enormous amount of TiO2. It is mostly found in heavy mineral sands in shallow marine environments. Countries such as Australia, Kenya, India, South Africa, and Sierra Leone account for the major titanium-bearing rutile sediments across the world.

MINING AND EXTRACTION

Open pit mining:

The mining of the ore begins with digging an open pit to extract the mineral sands. The collected mineral sands are then separated using the gravity separation method. The ore obtained contains 90% TiO2 in rutile and 60% TiO2 in ilmenite, which is increased to 93% TiO2 through a combination of pyro and hydrometallurgical techniques. Only 5% of these ores are converted into metallic titanium; the rest are refined into titanium dioxide for various purposes. The Tellnes mine in Norway is one of the largest open pit mines in the world, extracting 600,000 tons of titanium globally.

Wet Placer mining:

In wet placer mining, mineral sands are extracted from shallow marine beds or river beds and separated through the sifting process. The extracted titanium mineral ores are then processed and refined into titanium and TiO2. The Moma titanium mine in Mozambique is one of the largest wet placer mines in the world, contributing 850,000 tons in 2020.

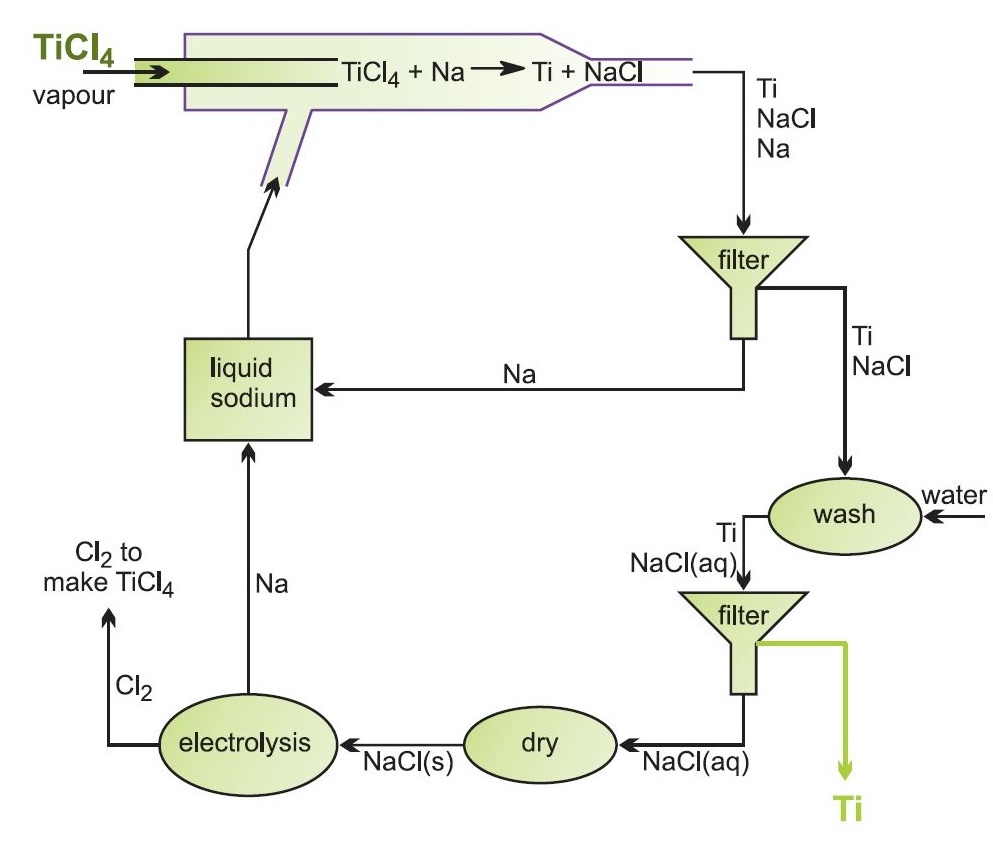

Extraction of Metallic Titanium:

The production of Titanium Metal involves either Kroll's process or the Carbo-Chlorination process. Initially, TiO2 ore is broken into small pieces and heated with liquid petroleum coke in the presence of chlorine. This conversion turns TiO2 into gaseous TiCl4, which is then passed through a condensation chamber to extract pure liquid TiCl4, typically up to 99% pure. Subsequently, it is introduced into a chamber containing molten magnesium, with inert argon gas present to prevent oxygen contamination of the material.

The resulting product undergoes continuous distillation for several days by heating up to 1000°C. During this process, titanium chloride is reduced to titanium, and magnesium is converted into magnesium chloride.

The final titanium is obtained in the shape of frills of sponge which are melted to produce titanium. These are made to remelt again and again for a quality product. Thus the pure titanium metal is obtained.

APPLICATION:

About 95% of the titanium ore extracted from the Earth is intended for refinement into titanium dioxide, a strongly white, long-lasting pigment used in paints, paper, toothpaste, and plastics. It is also utilized in cement, gemstones, as an optical opacifier in paper, and as a strengthening agent in graphite composite fishing rods and golf clubs.

Related Mining