Zeolite

ZEOLITE:

Zeolite is a light greenish-colored rock comprised of microporous, aluminosilicate minerals, commonly employed as commercial adsorbents and catalysts. These minerals are hydrated aluminosilicates of alkaline and alkaline earth metals. There are over 40 forms of zeolite utilized for various commercial applications. Some of the common types include analcime, chabazite, clinoptilolite, erionite, ferrierite, heulandite, laumontite, modernite, and phillipsite. Among these, clinoptilolite zeolite stands out as a widely used variant across numerous applications. Additionally, more than 250 zeolites have been artificially synthesized for commercial purposes.

SOURCES OF ZEOLITE :

Zeolites occur naturally and are also produced manually for industrial purposes. They are the main mineral component found in volcanic rocks formed through alteration in various geological and environmental conditions, such as temperature changes. Over many decades, layers of volcanic rock exposed to high temperatures and pressure give rise to a diverse group of zeolites. Zeolites form when volcanic rocks react with alkaline groundwater.

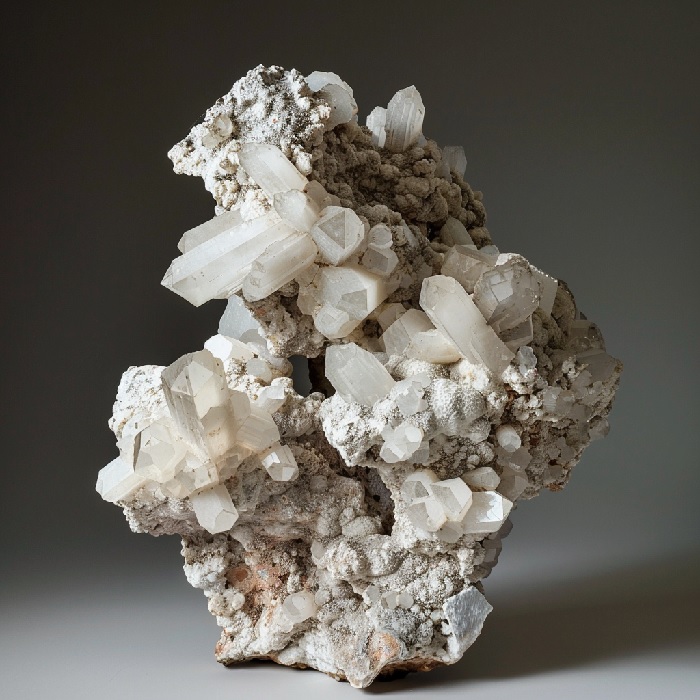

The Clay quartz mordenite heulandite zeolite stilbite thomsonitemesolite-scolecite chabazite calcite

MINING :

Conventional open-pit mining is utilized to extract natural zeolites. The zeolites deposited on volcanic rocks are retrieved by removing the topsoil or overburden material. The overburden can be easily removed when the ore is readily accessible. However, if there are difficulties in removing the ore or if the overburden covering the zeolite ore is hard, explosives are used for blasting. Modern machinery, such as tractors equipped with ripper blades and front-end loaders, is employed to remove the ore. The extracted ore is then sent for further processing.

ZEOCEM :

ZEOCEM, VSK PRO-ZEOLIT, and SLOVZEOLIT are the three zeolite companies that control all other small mining quarries in Slovakia. ZEOCEM, in particular, is one of the leading mining companies, constituting about 85% of the total production in the country. The common mining method used in these areas is open-pit mining. The popularity of rich and pure zeolite availability has surpassed that of any other zeolites.

CANADA :

C2C Mining and Zeo-Tech Enviro Corp acquired more than 10 mineral deposits. In this site, the deposits in the area are enriched with different forms of zeolite including chabazite, thomsonite and stibilite in varying amounts. Almost all the quarry uses conventional open pit mining to remove the ore. The removed ore is particularly used as a lightweight concrete.

TURKEY :

Rota mine is one of the leading natural zeolite producers and exporters. It was founded in 1995 in Turkey, the company has obtained high quality reserves in Gordes.

ZEOLITE MINING IN USA :

According to the survey conducted by the geological survey in the year 2017, eight companies in the USA operated 11 zeolite mines that are clinoptilote zeolite. It produces an average amount of 79,000 tons per year and is estimated to increase in the later year. It is primarily mined in California, Idaho, New Mexico, Oregon and Texas, in which the top 3 zeolite companies produce about 85% of the total production in the US.

ARTIFICIAL SYNTHESIS :

Many synthetic zeolites are produced around the world for custom applications.As the demand of the zeolite increases, artificial synthesis is used to produce the zeolites. It is synthesized by the process of slow crystallization or by the process of solidification. In this process the atoms or molecules are formed into structure in the repetitive pattern to form the crystal.

ZEOLITE PRODUCTION:

The annual production of zeolite is found to be approximately about 3 million tons. Some of the countries to constitute are China, South Korea, Japan, Jordan, Turkey, Slovakia and the USA.

Since the world reserves of the zeolite is not estimated, many countries do not report or delay to report the production of natural zeolites.

PROCESSING :

In processing, the naturally occurring zeolites are purified and extracted to eliminate the impurities and other minerals from the ore. The mechanical dispersion and differential suspension to remove the majority of the clay content of the ore. Then the contaminants with higher mass are removed by demineralized water instead of chemical flocculating agents. The removed ores are sent to the crusher where it is crushed to different sizes, it is then sent for the process of drying and milling. The milled ores are then classified according to the particle size and then are shipped for various purposes.Consumption of Zeolite all over the world.

USES :

The main causes of zeolite elaboration are:

1. Doping: Doping is the process of introducing an impurity into the zeolite structure in order to increase or modify certain desired properties. This can be done by introducing elements such as metals or organic molecules.

2. Aging: Aging is the process of allowing the zeolite to undergo chemical and/or physical changes over time. This can result in changes to the structure, porosity, and surface area of the zeolite.

3. Post-Synthesis Treatments: Post-synthesis treatments are processes that are used to further modify the properties of the zeolite. This includes treatments such as ion exchange, steam activation, and thermal treatment.

4. Synthesis Conditions: The synthesis conditions used to create the zeolite have a large impact on its properties. This includes the type of reactants used, the pH and temperature of the reaction, and the duration of the synthesis.

5.Zeolites are extensively utilized as ion-exchange beds in both domestic and commercial water purification systems, as well as in softening and various other applications.